Pressure mapping with DIY foam load cells

I had an idea a while back to make a pressure sensing pad for testing saddle fit on horses. The intent was to create an array of pressure sensing cells, which could then be used to produce a pressure map that would represent any pinch points on a horse’s back. I found that you can buy this sort of thing, but it’s way too expensive for the average guy. I decided to try and make my own for cheap. I ended up making one from a handful of copper-clad PCBs and 1/4″ shipping foam.

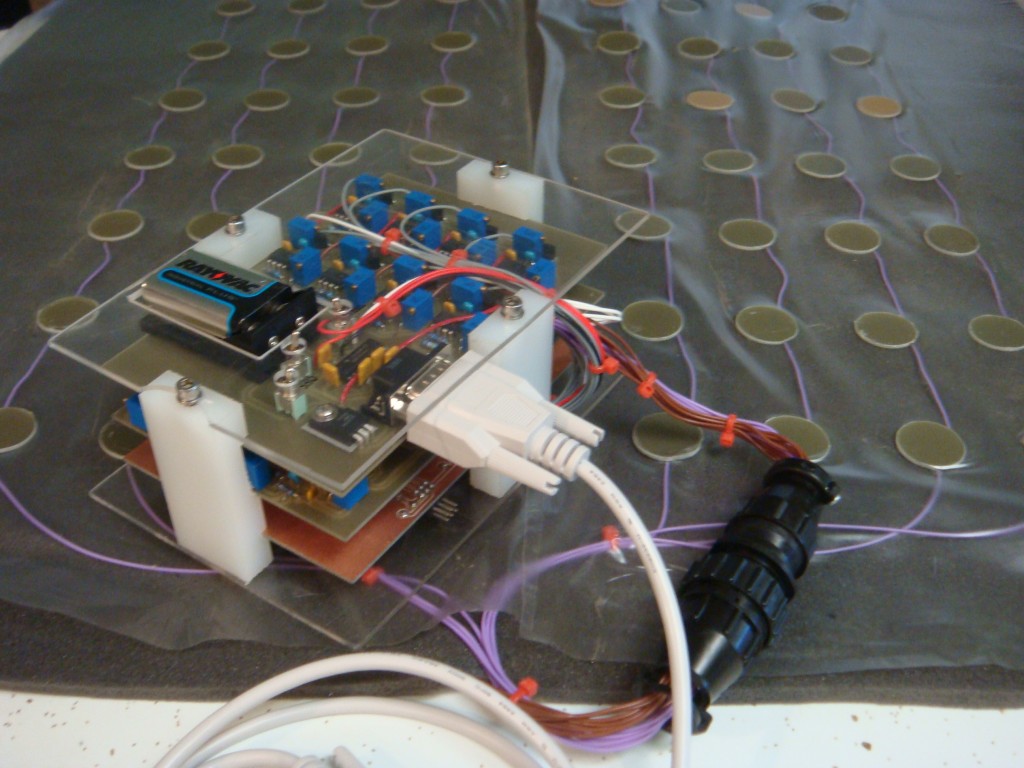

The active area of the pad is approximately 2′ x 2′. I think the foam is polyurethane open-cell foam but I’m not sure. It’s the stuff you use to pack shipping crates. The load cells are made by sandwiching the foam in between 1″ circle cutouts of copper-clad FR4 PC board. I used single sided board and a hole saw with the pilot bit removed (use a drill press and a clamp). The capacitance varies as the foam compresses, and the amount of capacitance is directly related to the thickness and density of the foam, as well as the area of the copper conductors (plates). So you can create any size or thickness load cell you want really. A bigger plate results in more capacitance, as does placing the plates closer together. I estimated the capacitance I would have in my application with this calculator I found at Daycounter engineering services.

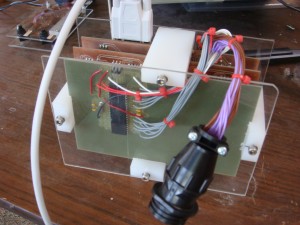

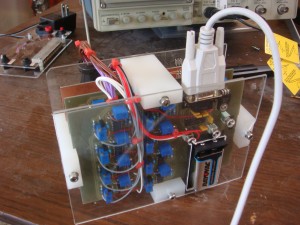

I created an array of 64 cells by making 8 rows and 8 columns, each with 8 copper-clad discs. Wherever the row/column discs align a load cell is created. An AVR typically has eight available ADC inputs along with another eight control outputs, so this way you can scan down through the rows and columns to measure each cell. A square wave is sequentially output on the columns, and after some analog proccessing the AVR’s ADC scans each row. The analog voltage present represents the amount of pressure (capacitance) at each site.

The square wave generator is the old two op-amp ramp generator/comparator circuit. This is fed to one side of the cell. The output from the other side is coupled through whatever capacitance is available at the cell, and results in a triangle wave with amplitude proportional to the capacitance thanks to a transimpedance amplifier. Then it is fed to a peak detector and amplified. The signal is then sent to the ADC. There are more than a few examples out on the web for capacitance sensing, here is a good one.

The AVR outputs the 64 values on a serial port. I used excel’s surface chart to represent the data. The chart posted here is a map of an english saddle.

It works fairly well, but my analog section needs some improvement. Sensitivity is sufficient for this test, but it’s relatively poor. Response time also suffers because of noise; my prototype could definitely use improvement in that area and I had to decrease the response time of the amplifier to get consistent output. This is unfortunate because I had planned on trying to make a movie by recording real-time data while riding a horse. I even designed it to run on a 9V battery for this purpose. Maybe if I have enough free time next summer (unlikely) I’ll try and tune it up a bit.

9 Comments to Pressure mapping with DIY foam load cells

Leave a Reply

Other Stuff

Recent Posts

- 6CY7 dual triode valve amplifier

- Air quality sensor (TVOC and eqCO2)

- Automotive rear fill “surround sound” with Boss DD-3

- Spring tester / weight scale

- Ducati 749/999 Tail Light

- Instruments for the GSXR

- Light pipe tail light for the GSXR

- M17x 6990m / 6970m overheating

- PAR / Spectrum analyzer

- Acrylic polishing and scratch removal

Archives

- May 2019 (2)

- April 2017 (3)

- October 2015 (1)

- May 2015 (1)

- March 2014 (2)

- December 2013 (1)

- July 2013 (1)

- November 2012 (1)

- October 2012 (4)

- September 2012 (1)

- August 2012 (3)

- June 2012 (1)

- March 2012 (1)

- February 2012 (1)

- January 2012 (1)

- October 2011 (3)

- July 2011 (1)

- June 2011 (3)

- May 2011 (2)

- April 2011 (1)

- December 2010 (1)

- August 2010 (1)

- July 2010 (3)

- April 2010 (2)

- March 2010 (2)

- January 2010 (2)

- December 2009 (2)

- October 2009 (2)

- September 2009 (1)

- August 2009 (15)

Hi,

would you be interested in selling your saddle fit system?

Thanks,

Dana

I originally intended on developing a product I could sell, but I never developed it past a prototype. I haven’t had time. As such, I don’t have anything I could sell at this point. Thank you for your interest.

Hi, am a M.E student am doing the same project .. i need your help sir .how can i contact u .. my contact is 9444572319… am in chennai .. please reply me help me

very good work. Im doing a pressure mat system thing as the project for my engineering diploma.

i was wondering if you could share what would need to be done to reduce the interference and increase sensor sensitivity?

much appreciated

j.s

Thanks. I’m not really the best analog designer, so I’m not sure exactly where the noise was coming from. I know that for starters I would definitely use smaller single layer components to decrease track length and allow a ground plane (I used DIP packages and through-hole stuff because it’s what I had). I am guessing that noise coupling happened mostly on the wires between the receiving sensor pad and the transimpedance amplifier. The transimpedance amp probably needs to be tuned pretty well to reject noise but not slow response. Since the transimpedance amp’s output is a triangle wave, I would probably start there with an oscilloscope and get it as clean as possible with a filter network.

My suggestion would be to use a 2nd order sigma/delta ADC to do your conversion. That way you get a digital value out and eliminate a significant amount of analog error issues. Additionally you can should use coaxial cable from your sensor pad to the ADC chip. That way you will get rid of the significant parasitic capacitance present in the sensor leads.

Hi,

i am interested to buy one too, maybe to help (just with money) to finish this project.

This is my mail : avenir@gmx.com

Stéphane

Did

you do any more with this project?

Thanks

No. There’s already patents on this and other companies selling similar products so I didn’t feel it was worth developing.